The modern competitive world of business is making the firms aware of the loopholes that have been lying in its fabric since long and have been taking the productivity down. In this scenario when one company needs to elbow out the other in order to stay afloat and relevant, one must eradicate these issues at once. The world of warehousing bears no exception. With the customer demands fluctuating and the multi-tier supply chain becoming the norm, warehousing is becoming a complex affair and it needs advanced warehouse management systems to perform tasks efficiently and with less errors.

With the advent of sound WMS, one problem that the DC managers have been made aware of is deadheading. Deadheading refers to driving empty vehicles or walking empty handed within the warehouse. And according to surveys, deadheading can damage the productivity of a warehouse by almost halving it. The solution to root out this problem that eats into profitability is task interleaving. This article tries to explain what task interleaving is. But before that let us shed light on how WMS works.

A standard warehouse management system takes into cognizance the pool of work that lies on a distribution centre’s floor. The work can range from picking to putaway and from truckloading to replenishment. WMS assigns specific works to specific workers, especially vehicle-driven operators or scans locations and pallets through voice terminals and RFID so that correctness in functioning can be ensured.

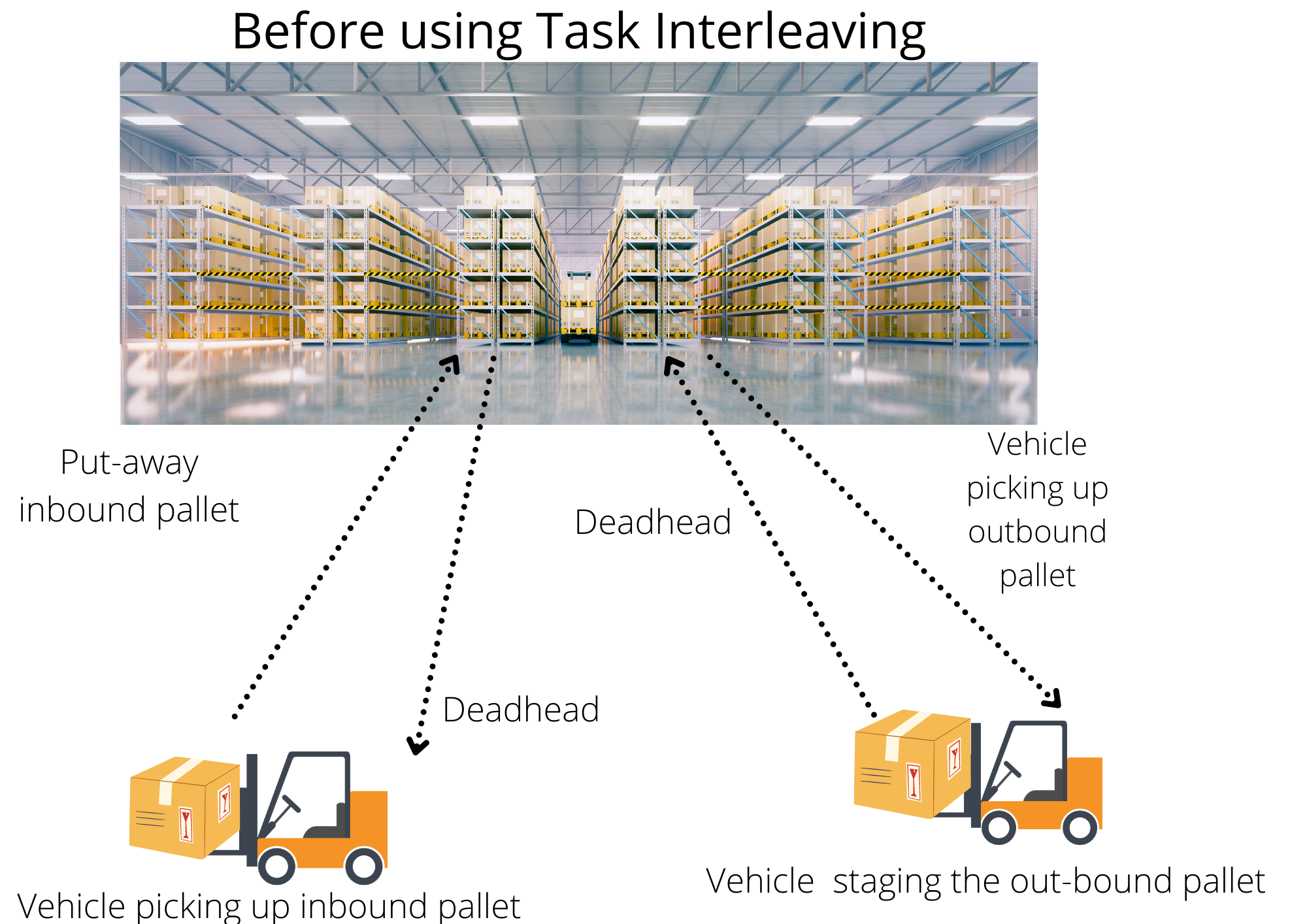

WMS assigns these tasks on the basis of various factors, such as permission, priority and closeness et al. It understands whether the workers who are being assigned have the requisite training or permission to perform that particular task. Moreover, the most important tasks would be assigned to the immediately available worker on the basis of priority. Also, if the location of the task is near the location of the worker or the vehicle, assigning that task is easier and convenient for the system. Prioritising tasks can be altered and the commands of the WMS can be flouted by the real-time situations on the work floor, thus establishing the flexibility of the warehouse management systems. The following graphic delineates how the operatives of a warehouse would function without task interleaving.

However, in this tradition work culture, a lot of time can get wasted if the workers or mobile equipments come empty to their source after the completion of the task assigned to them. The feature of task interleaving, apart from taking into consideration various types of work on the floor, tries to link all these functions so that the problem of deadheading is ruled out and cost effectiveness emanating from it adds to the productivity curb.

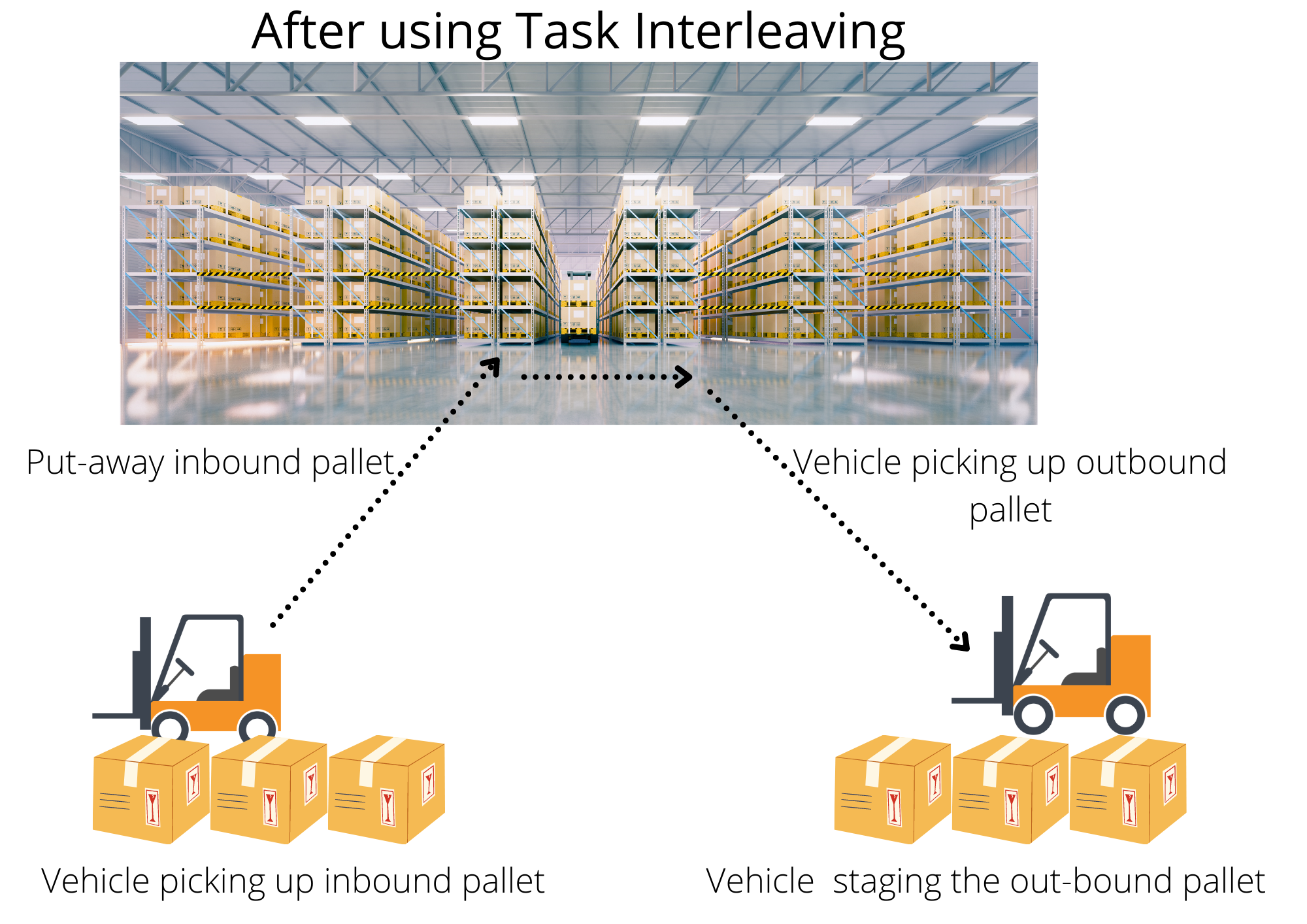

While in a traditional warehouse, mobile operators lay stress on particular form of works, by combining different tasks together and assigning multiple tasks to a single operator, the efficiency is increased manifolds. For example, the WMS can identify that there is a location where pallets are lying to be picked. On the basis of priority, closeness and permission, the WMS sends commands to the mobile-based operatives to do that complementary work and someone who has just completed a task of putaway nearby would come to perform the task. In this way, efficiency of the workers can be increased and cost justification can also be established. The graphic that comes below shows how smoothly and effectively a DC would function if task interleaving is adapted in the WMS.

It is advisable that the companies which are bracing themselves to implement task interleaving in their existing warehouses or are planning to build a new distribution centre to house task interleaving should design the layout in such a way that is comes as a convenience to the operatives. Though the gain in productivity is very much conspicuous, the expenses to harbour changes are quite noteworthy also. Thus, the warehouse managers must look before they leap and take into consideration all the operational complexity that can get incurred in the process of implementation of WMS with task interleaving features.